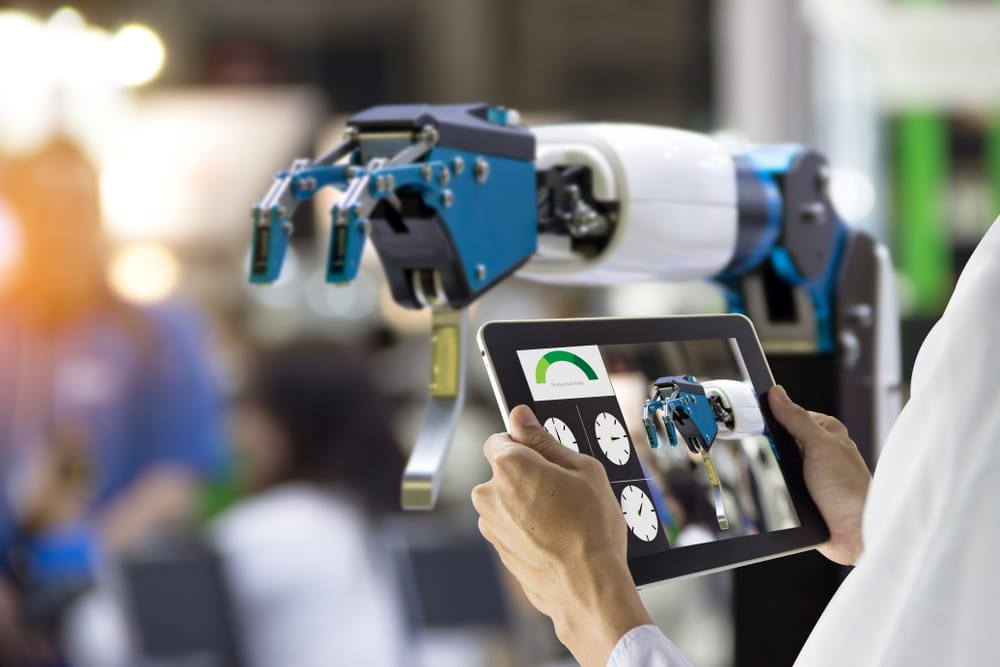

Different types of tests are required for different types of equipment to provide information about our products. The strength and durability of each material are some of the properties of the test. This is exactly what the universal testing machine is designed for. The purpose of the machine is to determine whether the material has sufficient strength and durability.

The machine is capable of pulling, compressing, bending, or stretching material beyond breaking and is used in industrial plants to test objects to see if they have fulfilled the task they have designed. Several vertical parts located on the base are marked in the universal tester. The second plate contains connectors for holding the sample and moving it during the stress test.

The most well-known test performed by a universal testing machine is the determination of hardness. This is accomplished by holding one end of the sample and pulling the other end until the opposite sides are destroyed. The flexural strength test follows the same pattern. However, instead of pulling, the machine pushes the end of the sample. The machine is multifunctional and can be used to determine various material properties. Only a few materials are malleable enough not to break, resulting in an unfinished product.

The universal testing machine is used for various tests.

The abrasion and pressure test is also applicable to universal test equipment. The metal cutting edge is introduced into the material at a constant speed until a piece of sample is cut during the shear test.

Current types of UTM testing machines use digital control and programming, which eliminates the need for a specific recorder, which was originally used to log test results for analysis and interpretation by a subject.

Purpose of a universal testing machine

The universal testing machine has the following features:

- Used to determine the tensile strength of a material.

- Used for compression testing.

- An adhesion test can be performed using the device.

- Prognostic exercises.

- The machine was used to perform a hysteresis test.

Why is it used?

Traction testing is one of the most common applications for universal testing machines. It is used to determine how strong the material is and how far it can go.

- Compression test: The compression test is not the same as the tensile test. Everything can be compressed with a universal test device. Everything can be squeezed until it breaks. The pressure test is performed to determine the breaking point of the material.

- Skin test: The skin test is the same as the skin test. The main difference is that one piece of material is torn apart by a tensile test, while two confined materials are pushed by a skin test to measure the strength of the skin. One of the main differences between the skin test and the tensile test is this.

Conclusion

The UTM machine tool is known as Universal Testing Machine because it has many applications. There are a number of universal machine testing solutions available and you can contact your provider to obtain them. It simplifies most of the work because it works as an all-in-one machine for performing important tests, and it is no longer difficult to verify several parts of the material because it can be done at once. Know more about the UTM and cement testing equipment at the Heicoin for more details.